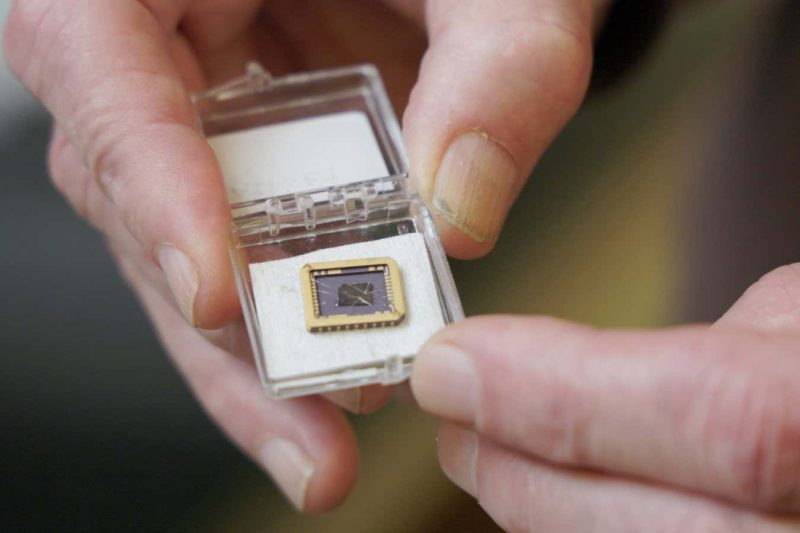

The workforce’s graphene gadget, grown on a silicon carbide substrate chip

Georgia Institute of Know-how

A working, scalable semiconductor has been created from graphene for the primary time, probably paving the way in which for a brand new sort of pc with larger pace and effectivity than right this moment’s silicon chips.

Graphene is a fabric constructed from a single layer of carbon atoms that’s stronger than metal at comparable thicknesses. It’s a particularly good electrical conductor and is extremely immune to warmth and acids. However regardless of its benefits, a working graphene semiconductor, which might be managed to conduct or insulate electrical energy at will, has evaded scientists. Such semiconductors are key to creating the logic chips that energy computer systems.

The issue has been the dearth of what’s often known as a bandgap. Semiconductors have bands of upper and decrease energies and some extent – the bandgap – at which excited electrons can hop from one to the opposite. This successfully permits switching on and off of the move of present, so it’s both conducting or not conducting, creating the binary system of zeroes and ones utilized in digital computer systems.

Whereas earlier analysis has proven that graphene might be made to behave like a semiconductor on a small scale, it had by no means been scaled as much as sizes that may make a pc chip sensible. Earlier work has proven that wrinkles, domes and holes in graphene sheets can have uncommon results on electrical move, creating the likelihood that logical chips might be made by creating the correct panorama of flaws. However so far, nothing has scaled up.

Now, Walter de Heer at Georgia Tech in Atlanta and his colleagues have created graphene with a bandgap and even demonstrated a working transistor, an on/off swap that both prevents or permits present to move via it. Their course of ought to be extra conducive to scaling up as a result of it depends on methods not dissimilar to these used to create silicon chips.

De Heer’s group used wafers of silicon carbide that had been heated, forcing the silicon to evaporate earlier than the carbon, successfully leaving a layer of graphene on high. De Heer wasn’t accessible for interview on the time of writing, however said in a statement that {the electrical} properties of a graphene semiconductor had been much better than these of silicon chips. “It’s like driving on a gravel street versus driving on a freeway,” he mentioned.

Silicon chips are low-cost to make and are backed by monumental manufacturing infrastructure globally, however we’re reaching the bounds of what these chips can do. Moore’s legislation states that the variety of transistors in a circuit will double roughly each two years, however the charge of miniaturisation has slowed in recent times as engineers attain circuit densities past which electrons can’t be reliably managed. Graphene circuits might reinvigorate progress, however hurdles stay.

“The actual fact they’re utilizing wafers is essential as a result of that’s actually, actually scalable,” says David Carey on the College of Surrey, UK. “You should use all of the expertise that the entire semiconductor business is completely comfy with to scale up this course of.”

However Carey is sceptical that the event means the world will quickly shift from silicon to graphene chips, each as a result of the brand new analysis wants a lot of refinement by way of transistor dimension, high quality and manufacturing methods, and since silicon has such a headstart.

“Most individuals who work on silicon are bombarded every day by new, great supplies which are about to exchange it and none of it’s ever occurred,” he says. “For those who’re a silicon individual, you’re fairly fortunately sitting on high of the mountain. The concept that I’m going to exchange my laptop computer with graphene isn’t fairly there but.”

Matters: