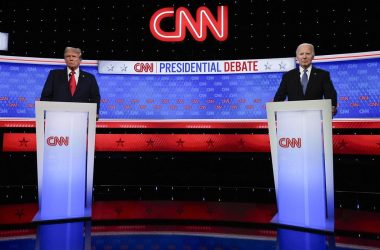

Aluminium refinement produces a hazardous pink sludgeAjdin Kamber/Shutterstock

The massive reservoirs of hazardous pink mud which are produced as a part of refining aluminium may very well be used to make greener metal.

There are roughly 4 billion tonnes of pink mud saved around the globe, which is an environmental hazard that may result in lethal accidents. And producing a tonne of metal generates almost 2 tonnes of CO2 – that’s as a result of most metal manufacturing includes burning fossil fuels to react carbon with the oxygen in iron ore, yielding iron but additionally carbon dioxide.

Isnaldi Souza Filho on the Max Planck Institute for Iron Analysis in Germany and his colleagues have give you a option to deal with each issues. They’ve devised a technique to extract iron from pink mud by exposing it to a plasma of hydrogen and argon, after which utilizing this iron to supply metal.

Key to the method is that pink mud comprises between 30 and 60 per cent iron oxide by weight, alongside hazardous components equivalent to arsenic and lead.

The researchers heated up pink mud in a tool referred to as an electrical arc furnace to a temperature of roughly 1850°C (3362°F), with a mix of argon and hydrogen to react with the oxygen. The ensuing soften was then cooled, crushed and separated into iron pellets able to be became metal.

Co-author Matic Jovičević-Klug, additionally on the Max Planck Institute for Iron Analysis, says that given the quantity of pink mud there may be, the method may produce between 748 million and 942 million tonnes of metal, which might end in over a billion tonnes much less of CO2 in contrast with typical strategies. Nevertheless, this scale would nonetheless solely be a fraction of the metal produced globally every year.

Utilizing inexperienced hydrogen as a part of the refining course of will not be a brand new thought, says Mark Jacobson at Stanford College in California. In 2021, a Swedish consortium referred to as HYBRIT demonstrated a trial run that lowered the carbon footprint of steelmaking by as much as 98 per cent. What’s new is utilizing the hazardous pink mud as a feedstock, he says. “Whether or not it’s cheaper than the primary course of is troublesome to inform,” says Jacobson. “The authors declare it’s cheap, however extra data is required to find out this.”

Subjects: